Automotive Parts Manufacturing

The Definitive Guide to Automotive Parts Manufacturing

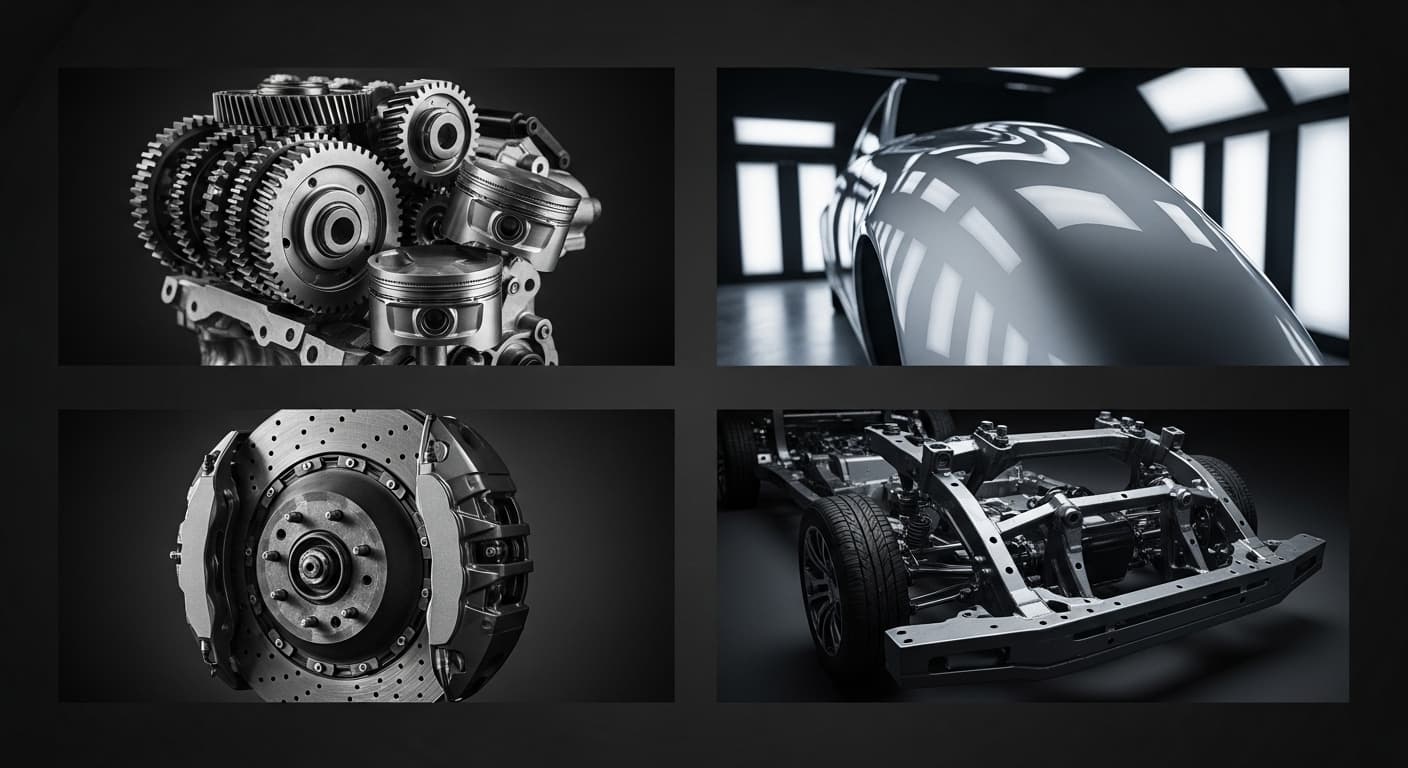

From transmissions to body panels, from complex gears to sleek contours, every motor vehicle is assembled from thousands of precision components. This field, which blends digital design, advanced materials science, and cutting-edge technology, is a critical area in the automotive industry, dedicated to creating high-quality auto parts with unprecedented speed, precision, and flexibility. This transformation is driven by ongoing innovation—the rise of electric vehicles (EVs), the sophistication of autonomous driving systems, and the ongoing demand for safer, lighter, and more efficient vehicles.

Modern manufacturing encompasses a wide range of technologies, from rapid prototyping to on-demand production using techniques like CNC machining and injection molding. Modern manufacturing aims to leverage technology to create stronger, more reliable parts at unprecedented speeds. But what are the core processes, materials, and quality standards you need to understand in the automotive sector?

Core Manufacturing Processes for Automotive Components

Automotive parts are produced differently in different regions, and the right manufacturing process further impacts a part's strength, weight, cost, and performance. Whether you need a single prototype or a small batch of custom automotive parts, the ideal manufacturing process depends on the specific application. Below, we'll introduce several common precision component manufacturing processes.

CNC Machining: Precision for Complex Engine and Powertrain Parts

This subtractive process uses computer-guided tools to precisely remove material from a solid block of metal or plastic, achieving incredibly tight tolerances. CNC machining is essential for manufacturing critical engine parts, transmission components, and other powertrain elements where performance and reliability are crucial. From lightweight aluminum to high-strength steel, CNC machining delivers unmatched accuracy for the most demanding applications.

- CNC Machining Service- When you need to solve complex parts, choose our benchmark.

Sheet Metal Fabrication: Shaping the Vehicle's Chassis and Body

This process involves cutting, bending, and forming flat sheets of steel or aluminum into the robust structures that make up a car's frame. It is the fundamental method for creating the automotive chassis, support brackets, enclosures, and sleek car body panels. By providing an excellent strength-to-weight ratio, sheet metal fabrication is indispensable for building vehicles that are both durable and efficient.

- Sheet Metal Fabrication - The backbone and skin of a vehicle rely on the strength and versatility

Vacuum Casting: High-Fidelity Prototypes & Low-Volume Production

This process uses a master pattern to create a silicone mold, which is then used to cast high-fidelity polyurethane copies. It is perfect for creating a small batch of realistic automotive prototypes for functional testing, marketing showcases, or fit checks. As a cost-effective method for low-volume production, it is ideal for custom interior components, housings, and bezels where aesthetic quality is key.

- Vacuum Casting - The cost-effective solution for accelerating product development.

Material Selection in Automotive Manufacturing: Metals, Plastics, and Composites

A perfectly executed manufacturing process is only half the equation; the material itself defines a component’s ultimate character. The choice of automotive materials is a critical engineering decision, balancing factors like strength, weight, thermal resistance, and cost. From the robust chassis to the intricate dashboard, every part's material is selected to meet specific performance demands. Modern automotive design leverages three primary material families:

- Common Metals: Aluminum, Steel, and Titanium

Metals are the traditional foundation of automotive construction, valued for their strength and durability.

- Engineering-Grade Plastics & Polymers

Materials like ABS are common for interior trim and grilles due to their impact resistance and finish quality.

- Advanced Composites for Lightweighting

Once reserved for supercars and racing, composites are increasingly used in mainstream vehicles for structural components, body panels, and EV battery enclosures.

From Digital Design to Physical Part: The Manufacturing Workflow

Physical car parts begin as digital ideas. The entire process from screen to reality follows a structured workflow designed to ensure quality, efficiency, and cost-effectiveness. We perform these essential steps before production, ensuring every part we produce meets specifications.

- Stage 1: Design for Manufacturability (DFM) Analysis

This model undergoes a critical DFM analysis, where engineers identify and resolve potential production issues.

- Stage 2: Prototyping and Functional Validation

Once the design is optimized, we use rapid prototyping processes to manufacture prototypes, test and evaluate them, and verify performance.

- Stage 3: Tooling and Production Setup

Before production begins, the necessary tooling is created and the machine programming is set up to ensure the precision and quality of each part.

The Non-Negotiables: Quality, Standards, and Compliance

In the automotive industry, quality isn't an option—it's the bedrock of safety and reliability. Our entire operation is built on a foundation of verifiable quality, rigorous industry standards, and unwavering compliance. For our partners, this means reduced product risk, supply chain stability, and complete confidence in every part we deliver.

- IATF 16949 Certified: The Gold Standard in Automotive Quality Management

- Proof of Precision: CMM & Production Part Approval Process (PPAP)

- Process Control & Traceability: Statistical Process Control (SPC) & IMDS Reporting

Startups or Innovative Technology Partners We Support

We are more than just a manufacturer in a complex automotive ecosystem; We are committed to providing seamless integration, on-time delivery, and proactive communication to ensure your supply chain runs efficiently and smoothly, helping you gain a competitive edge in the market.

Manufacturing for the Electric Vehicle (EV) Components Market

We have the expertise and technology to manufacture high-precision EV components. Product Development: Battery pack enclosures、Motor parts、ECU housings(electronic control unit)、Sophisticated thermal management system parts.

Manufacturing for the Racing Components Market

We leverage advanced materials like specialty alloys and composites. and cutting-edge precision machining to build custom suspension systems, powertrain parts, and aerodynamic components. Meet your needs for lightweight, high-strength, and durability, and gain a competitive advantage.

If you need to discuss material selection or complex assembly processing challenges, please contact our automotive parts engineers first. Or send a drawing, get an Instant Quote.

Medical Device Prototyping

Medical Device Prototyping

Automotive Parts Manufacturing

Automotive Parts Manufacturing

Aerospace Manufacturing

Aerospace Manufacturing

![[Guide Updated] Please See Our New Low Volume CNC Machining Page](/uploads/20250809/e0980b58d9f1528680f9fe34ae16af14.png) [Guide Updated] Please See Our New Low Volume CNC Machining Page

[Guide Updated] Please See Our New Low Volume CNC Machining Page